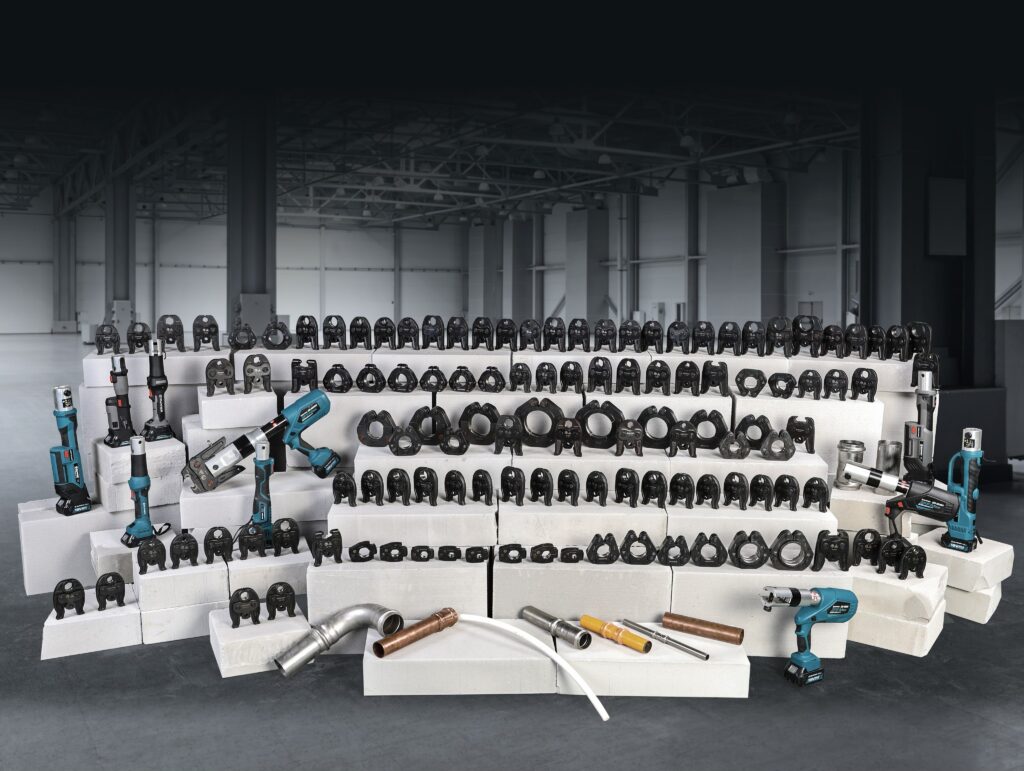

At Z-Press, sustainability doesn’t stop at performance. Our commitment extends through the full lifecycle of every hydraulic and brushless press tool we supply. Together with our manufacturing partner Zupper, we’re ensuring that all our products meet the highest standards of environmental responsibility under the Waste Electrical and Electronic Equipment (WEEE) and Electrical and Electronic Equipment (EEE) Regulations.

Understanding WEEE & EEE

The WEEE Directive (2012/19/EU) and the EEE Regulations exist to reduce the environmental impact of electrical, electronic equipment and batteries. These laws make producers and distributors responsible for the collection, reuse, recycling, and recovery of products when they reach end of life.

For professional tools like the Zupper MP-1930 press gun and other Z-Press products, this means ensuring that materials are handled responsibly, components are recycled correctly, and waste is minimised across the product lifecycle.

Zupper’s Commitment: Smarter, Sustainable Design

As the original equipment manufacturer, Zupper designs every press tool with environmental responsibility in mind. Key features include:

- Durability and Longevity: Each press tool, including the MP-1930, is engineered for thousands of reliable press cycles, extending its service life and reducing the frequency of replacements.

- Modular Component Design: Tools are built with replaceable internal parts, meaning damaged or worn components can be repaired or swapped rather than discarded.

- Battery and Electronic Recovery: Rechargeable Li-ion batteries and control electronics are manufactured to international safety and environmental standards and can be easily removed for recycling or reuse.

This design philosophy ensures that Zupper tools are not only powerful and precise but also aligned with a circular economy approach where resources are kept in use for as long as possible.

Z-Press Responsibility: UK-Based WEEE Compliance

In the UK, Zupper tools are sold under the brand name Z-Press and the importer and distributor Cubralco Ltd, taking on the EEE responsibility for all Zupper tools placed on the UK market. To comply fully with the WEEE Regulations, we have:

- Registered as a Producer under the WEEE Scheme: ensuring every tool sold is accounted for under UK environmental law.

- Established a Take-Back Scheme: customers can return end-of-life press tools, chargers, or batteries to Z-Press for safe recycling or refurbishment.

- Partnered with Approved Treatment Facilities (ATF’s): guaranteeing that electrical components and metals are dismantled and processed in line with UK environmental standards.

- Issued clear labelling and documentation: all Z-Press and Zupper products are marked with the WEEE symbol and carry end-of-life handling instructions.

Reduce, Reuse, Recycle: The 3 R’s of Z-Press

Our sustainability promise is built around the 3 R’s:

Reduce – by designing longer-lasting, efficient products such as the MP-1930, which features a brushless motor, optimised hydraulics, and intelligent power management.

Reuse – through our repair and reconditioning programme, extending the life of returned press tools.

Recycle – by dismantling retired tools to recover valuable materials such as copper, aluminium, and steel, ensuring minimal waste to landfill.

Continuous Improvement Through Partnership

The collaboration between Zupper and Z-Press means we’re able to monitor design, production, and post-use recovery as a joined-up process. From the initial design of a press gun in Zupper’s R&D lab, to its recycling at an approved UK facility, every step reflects our shared commitment to environmental stewardship.

This approach ensures that when a merchant, installer, or engineer chooses a Z-Press tool, they’re not just choosing precision and reliability they’re investing in a more sustainable future for the industry.

Looking Ahead

As WEEE and EEE regulations evolve, Z-Press continues to adapt and lead by example. Our upcoming initiatives include:

- Expanding our take-back programme through merchants and wholesalers.

- Introducing digital tracking of end-of-life returns.

- Collaborating with partners to explore remanufacturing opportunities for high-value components.

At Z-Press, compliance isn’t a box-ticking exercise it’s part of our route to success. Together with Zupper, we’re powering the next generation of environmentally responsible press tools, designed not just for performance today, but for the installer of tomorrow.